How to lay linoleum: the most detailed laying guide

Linoleum is a democratic floor covering that attracts not only with an affordable price, but also with the opportunity to do it yourself. In order not to spoil the inexpensive, but very much liked material, you need to thoroughly study the information on how to lay linoleum on different types of substrates. It does not fit to get acquainted with various tricks and nuances of styling.

Wearproof universal covering is suitable for arrangement of residential, industrial and public premises. Elastic waterproof material is laid in apartments, in large shopping and entertainment centers and in autonomous low-rise buildings.

Content

How to prepare a rough floor?

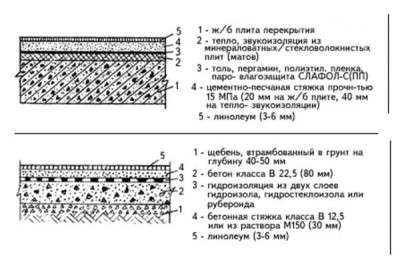

Among the most common types of roughing bases for laying linoleum:

- concrete floor slabs;

- wooden floors;

- sand-cement or polymer screed used to level the base.

However, as a rough base for linoleum, a tiled floor can be used, its class counterpart that has not worn out - still strong, previously laid linoleum and even parquet, if there are people who want to turn expensive natural material into a substrate for budget coverage.

Preparing for laying old wood floor

The most common question asked by owners of private property and housing in the buildings of the secondary fund: "How to lay linoleum on a wooden base?".

If after a detailed study of the state of the wooden floor there was no desire to remove it completely before overlapping, you will need to perform the following simple operations:

- check the tightness of the floorboards, hammer the protruding hats of the nails, strengthen all the elements that are not credible;

- dry floor with uneven upper level of the boards to align with scoring;

- fill the cracks with putty;

- rotten and damaged floorboards to replace with new durable material;

- if the floor is laid in logs, replace the damaged timber, if not, but noticeable lack of horizontal plane to level logs by putting sand or wood chips under them;

- Instead of scrapping, especially on the floor, causing suspicion of fragility, it is better to lay sheets of gypsum fiber board or plywood (in terms of the location of the elements of such a screed should resemble brickwork);

- fasten each element of a dry screed from plywood or GVL with screws specifically designed for the selected material, after which you should learn how to lay linoleum on plywood and carry out the planned laying.

At the end of the installation and fixing of the plywood sheets to the logs or to the floor, it should be walked around to determine the deflection and doubtful areas. This must be done, because from the unstable position of the plywood elements, the self-tapping heads can come out and break through the linoleum.All the insidious areas are best strengthened immediately by attaching pieces of fiberboard.

If the floor initially did not raise doubts about the reliability, it is enough to carry out scouring, primer and start laying without unnecessary expenses.

Preparation of concrete floor under linoleum

The whole process is to eliminate the linoleum precursor and repair the concrete rough foundation:

- If as a result of the audit deep cracks, chips, bumps, bumps are revealed, it is advisable to fill the screed. It will be possible to lay linoleum only after complete drying and hardening of the leveling layer.

- Minor deviations from the horizontal within 2mm distributed per square meter must be removed by sanding.

Attention. It is not recommended to level the concrete base floor before laying the vapor-tight linoleum using plywood and other materials that can absorb moisture from the floor, otherwise the floor will not last long.

After preparing the base from concrete, it remains to find out how to properly lay linoleum with glue or bonding mastic, and get to work, since this material is mainly glued to the concrete base. An adhesive can be used to treat the entire area of the room to be trimmed or to apply it partially along the perimeter and in the areas of maximum load.

In addition to the information received, watch a video on how to fix material by processing with mastic not the entire floor area - the video will help to visualize an unpretentious and very economical process:

Preparation of the "old linoleum" for the flooring of the new

The phrase "old linoleum"It was not without reason that it was in quotation marks. Really old, dust-absorbed, torn material needs to be removed and thrown away without the slightest regret. For those who decided to simply change the interior, laying on top of even stronger linoleum a more expressive new option, the predecessor will serve as an excellent insulating and leveling substrate.

Important. On the old linoleum, you can put only a single-layer brand.

Like any of the roughing preparations to be finished, the old linoleum must be dry, clean and free from greasy and varnish stains. Before gluing linoleum to any surface, it is better to cover the floor surface with a primer.

Even if the use of adhesive mastic is not planned, the primer will strengthen the top layer of the subbase, eliminate the appearance of dusty particles that have separated from the base and the spread of dust.

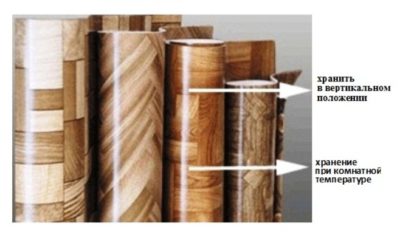

General requirements for all installation methods

Rolls of the material selected for finishing should stand for a couple of days in the room, and the stand is still, that is, in a horizontal position. Room temperature in their presence should not fall below 15? C and rise above 18? C. It is not permissible that the air humidity in the room during the period of the material getting used to the new conditions exceed the limit of 65%. These characteristics must be stable two days before gluing and in an equivalent period of time after.

The layout of linoleum sheets is oriented to the source of natural light - a window. Seams are recommended to be placed along the direction of the light flux, since with a transverse arrangement they will be too noticeable. How to lay linoleum with one canvas is absolutely indifferent, because its aesthetic indicators will not be corrupted by seams. Plain material is very simple to lay, the main thing is to leave 3-4 cm allowances for seams and 10 cm indents along the perimeter. Stripes of linoleum with a pattern should be stacked taking into account the report, combining elements of a repeating ornament.

The overwhelming majority of brands currently supplied to the consumer market are equipped with a jute or synthetic backing. Those who use these brands of stackers have no questions about what to lay under linoleum. If there is no insulation-leveling layer located on the back side, it is advisable to lay it yourself.

Which substrate to choose:

- Made from cork chips is too expensive and does not tolerate the load, especially from heels and thin legs of furniture. Well, if the choice "rested" in traffic, it is better to prefer the most durable brands.

- A substrate made of pure jute fiber is an expensive pleasure, which is its only drawback. It does not rot, does not even burn, and does not grow moldy at all.

- Linen fiber backing is quite suitable, it is in no way inferior to jute.

- The best option is a mixture of flax, wool and jute, impregnated with flame retardants and antifungal drugs.

It is not recommended to put penoizol under linoleum, since it does not differ in sufficient rigidity. Such a floor will lose its aesthetic appeal too quickly.

When arranging residential premises with baseless linoleum, the use of a substrate as a leveling and insulating layer is mandatory. As already mentioned, she is not requiredif linoleum is laid on top of its counterpart with a substrate.

Proper cutting

Often it is trusted to experienced professionals who know how to avoid end joints, how much and where to leave allowances and how to rationally spend material. Fundamentally, the process consists in cutting with the help of a special knife and a ruler of linoleum rolled on the treated surface. Along the contour of the room, indents and allowances for technological seams are bent on the walls. Cutting elastic material is best suited for this procedure.

There are four different ways to open the material:

- the material is adjusted at the installation site by pressing the edges in the mating zone of the floor and wall. After cutting around the room perimeter, technological gaps should remain to ensure thermal linear movements. An exception is the area of the entrance aperture;

- marking is done on the material spread out along the floor plane, after which it will be necessary to cut off the marking surpluses (this is done fitting without gaps);

- on a coating spread out in a room with a complex configuration, first mark out the protruding architectural elements, and then cut the linoleum along the marking;

- the marking is applied according to pre-made cardboard templates, which is required for flawless laying around pipes, plumbing, and other monolithically installed equipment.

Note. It is recommended that the holes in linoleum intended for pipes and plumbing be made not far from the butt weld.

After cutting, the coating lies on the floor for two days without fastening. This technological break is necessary so that the material is smoothed as much as possible and acquires stable geometric parameters.

Gluing - a method of laying in large rooms

Linoleum is not glued to the floor in rooms up to 20 m. That is, glue is rarely used for this.

With the advent of adhesive tape, most finishers were happy to be carried away by the option that increases the pace of finishing, and at the same time facilitates the dismantling process in the event of a change in “decoration”.You can see how to properly lay linoleum - the video demonstrates the installation of the floor using a tape with two adhesive sides, followed by sealing joints.

Two ways to glue linoleum:

- A binder with a notched trowel is applied to the surface of the subfloor, treating it first in the middle of the room. At the location of the butt joints, glue is not applied to the floor, leave about 12 cm dry. In the area where the floor is adjacent to the walls, the adhesive is required. The thickness of the binder layer is regulated by the manufacturer and depends on the brand of linoleum. In order to increase adhesion, the back of the material can also be treated with a thin layer of glue.

- Half of the canvas pre-spread across the floor rolls into a very tight roll, stopping in the middle of the room. Mastic is applied in a manner similar to the above option. Then, shaking the tight roll back and forth, glue the material to the base when rolling it, moving from the center of the room to the periphery.

All air from under the glued material needs to be expelled, carefully with effort to walk on the surface with a special roller or ordinary rags. Otherwise, defects and waves will appear due to partial peeling. They can arise due to the absence of gaps along the contour if the partially adhered coating begins to expand with increasing temperature.

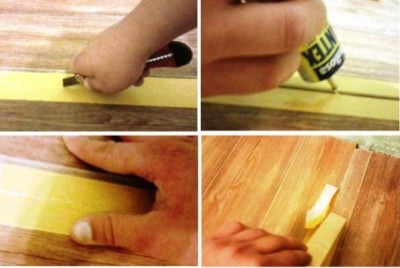

"Cold welding" - a neat beautiful seam

In order to make the seams almost invisible, they use the technique “cold welding»:

- The joint of sheets is glued with masking tape, it must be thoroughly fixed on the surface.

- A knife blade is buried in the seam and a glued tape is cut along it.

- A needle with a special glue is introduced into the incision and, dosing the composition, the incision is treated with it.

- The mating edges with the binder material must be pressed firmly.

- After a short period of time specified by the manufacturer of the product, masking tape is removed.

When punctually following the manufacturer's instructions, no trace of the used product remains. Usually, the seams are welded one day after gluing.

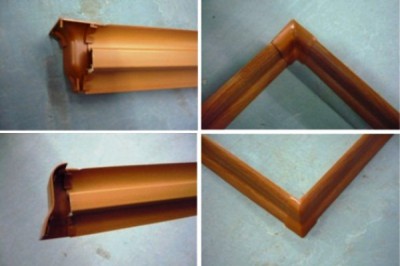

Finish the work by installing the baseboard.

It is not too difficult to lay linoleum correctly with your own hands. It is important not to deviate from the rules developed as a result of many years of practice and not to forget about the nuances of laying linoleum associated with the specific properties of polyvinyl chloride flooring. Studying technological features will help to avoid errors and damage to the material. Firmly glued linoleum will “faithfully” serve and delight the hosts for a long time.

4 comments