Soundproofing the floor: get rid of excess noise and anxiety with your own hands

Soundproofing the floor, walls and even the ceiling is relevant for those people who suffer from unbearably noisy or musically gifted neighbors. And when a child is born in the house, in order not to create problems and inconveniences for the tenants from below, they have to make soundproofing of the floor in their own home. In some cases, the problem of unpleasant sounds does not arise because of the human factor: the floors simply wear out physically and even just walking with it creates noise throughout the apartment. A properly noiseless floor absorbs not only sounds from outside, but also those that are created directly in an apartment or private house.

The order and features of the work

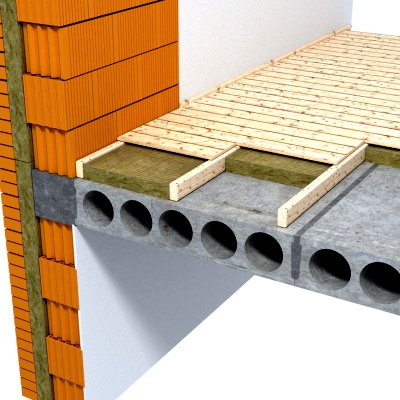

To solve the problems associated with “noisy floors”, the so-called “floating flooring” technology is most often used. She received this name because of the design features: screed, parquet or laminate do not touch the walls. If this condition is not met, then as a result there will be bridges between the floor covering and the wall that transmit sound. At the moment, materials of different quality, composition and effectiveness are used for soundproofing the floor, but most often a special substrate is used. It is laid in a layer up to 20 mm thick, depending on the type of floor.

Attention! Such a substrate reduces the level of air and impact noise, and its sound insulation coefficient is -21 dB. To achieve maximum effect, walls and ceilings are often soundproofed, but we'll talk about this another time.

Sound insulation of the floor, in some cases, is based on the use of special underground slabs, when laying which it is necessary to create an air gap of up to 10 mm between the wall and the edge of the tile. To set the required clearance, you can apply the remains of floor slabs, which, after installation and their fixing, are safely removed without violating the design. A gap of up to 2 mm is also necessary between the plates, and the plates themselves are fixed to the base of the floor using special glue or staples / nails.

Sound insulation of the floor in a prefabricated house does not tolerate errors, since any error significantly reduces the effectiveness of the sound insulation layer. In the process, DO NOT:

- create a snug fit of the plinth to the floor (only to the wall);

- hammer nails into beams through floorboards;

- disrupt the process of laying the substrate;

- allow clumping of soundproofing material.

Important! The substrate is laid at an angle of 45 ° relative to the joints of the floor covering. This eliminates the coincidence of the joints of the laminate (parquet) and soundproofing material.

What material is better to take sound insulation from?

Ideally, soundproofing the floor involves a combination of hard materials that reflect the sound wave and materials with a high sound absorption coefficient (mineral wool).

But here, there are also some drawbacks: due to the use of a combined substrate, the floor height will increase by 50 mm, which is more than noticeable for small apartments.

Note! There is a “natural” soundproofing alternative to the substrate - sound insulation made of coniferous wood. It is much thinner than combined substrates, but the effect is several times better.

Such a substrate is made of high-quality needles, and therefore is an environmentally friendly product. Its main parameters:

- high mechanical strength;

- resistance to stretching and compression;

- elasticity;

- low thermal conductivity;

- durability.

By the way! There are also many other artificial substitutes, which are based on foamed foam. Such substrates are much cheaper than wood counterparts, but they cope with their "duties" no worse. Additional thermal insulation is provided by special foil substrates that reflect heat.

A few words in conclusion + video example of styling

Before making soundproofing of the floor, it is necessary to measure the area of the room in which the work will be carried out. This will help to avoid wasting time on the purchase of the substrate. Do not lay the substrate in several layers, as this will increase not only sound, but also thermal insulation. When choosing a substrate, it is worth starting from the quality of the substrate and the type of future flooring. A mismatch in the parameters can lead to a low efficiency of the insulating layer, and, in fact, to no avail all the work done. The key to success is a calm and measured work, and the help of an extra pair of hands will always be welcome.

2 comments