How to remove “waves” on the floor: treat screed, linoleum, laminate and parquet

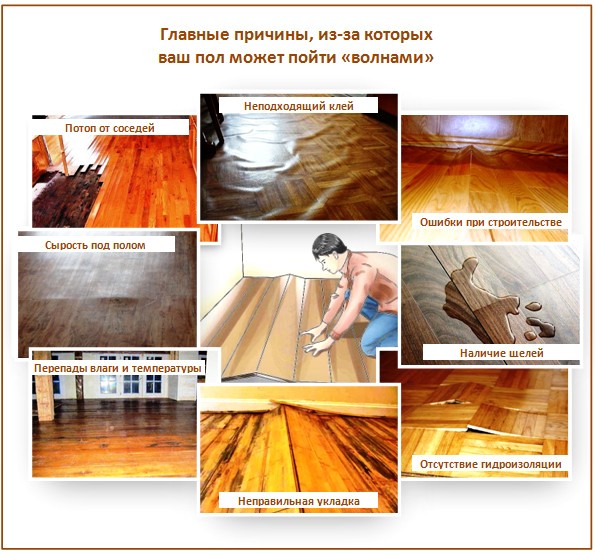

That’s what can lead to a desperate state, it’s whole “waves” that came from nowhere on the floor. They can be found upon arrival at the cottage or bathhouse, or right away, the very next morning in their own apartment. Moreover, "camels" can occur on linoleum, and on the carpet, and on the laminate, and on the floor, and even on a simple plank base. And there are even more reasons for this. Let's deal with each one individually and learn how to solve such problems in one day.

“Waves” on the floor are not so much unaesthetic as dangerous to the cover itself. Not to mention the fact that such a "hump" can easily be crossed and split your legs - you cannot warn all the guests. And each coating has its own reasons to go "waves".

Content

Level the laminate: have to sweat!

Despite the large-scale advertising and laudatory comments about the modern laminate, this coating is by no means the most persistent and picky. You just look at the photo below - do you think this is a rather rare situation? Not at all - just spill a glass of water. And also - there are a lot of other reasons why kids can grab cars and arrange real roller coasters on a completely flat laminate until recently. So, about the sources of such problems and proven solutions.

Reason # 1. Low quality

You probably purchased a very cheap Chinese handicraft laminate. And there is? Better immediately redirect to another. This is a futile fight.

Reason number 2. Installation Errors

As with linoleum, here it is also necessary to set aside the deformation gaps between the coating and the walls. Otherwise, deformation is inevitable, the first sign of which is generous waves over almost the entire coating. So, just remove the skirting board and mark with a pencil all the places where the laminate rests against the wall closely.

Sometimes the substrate and poor-quality preparation of the foundation itself are also to blame. Just do it right initially:

Reason number 3. Moisture

They spilled water and got "camels"? Do not be surprised. Laminate is a pressed wood shavings with sawdust, which quickly absorbs moisture and swells. Just remove the damaged boards and let them dry, but do not heat them on purpose. And if such a laminate is in the child’s room, and the situation is far from the first, then consult the seller and purchase special wax polishes for such a coating. They will repel water well.

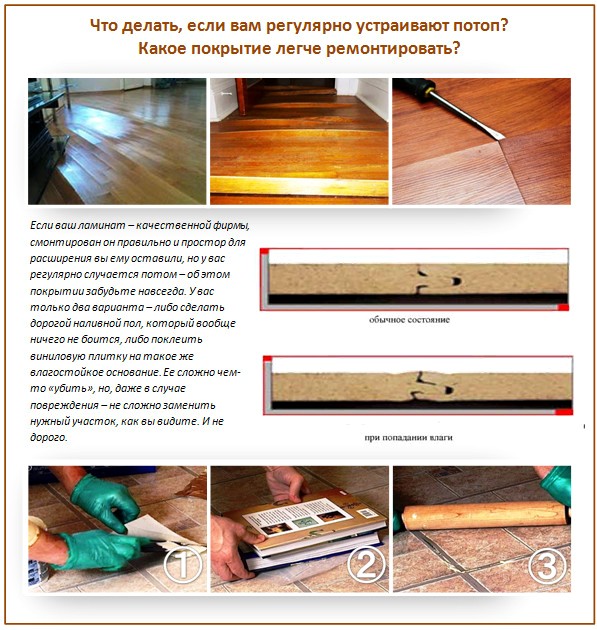

Reason number 4. Flood

But if water has been acting on the laminate for a long time, for example, not a day or two, while you were absent, then you will have to completely replace the damaged lamellas. Yes, it’s difficult to choose new ones in the exact thickness, texture and color - that’s why we always advise you not to throw away the residual material even at the stage of laying. If you don’t have one, don’t despair: for now, close it with what you found, and spend the time you won on new searches. By the way, in online flooring stores you will find a sample faster.

Reason number 5. Heating pipes

Where they exit from under the floor, the expansion gap should be exactly the same as the walls themselves.

Reason # 6. Door lock

If it is fixed directly to the laminate, it will begin to deform. It is necessary to cut a hole and fasten such a part directly to the screed.

Reason number 7. Some damage

Another reason for the swelling and swelling of linoleum is damage to the waterproofing. So, if there are chips on the board or its waterproofing layer was scratched before laying, problems will occur again and again. Just repair the seams with the most common soldering iron with a power of 100 watts or more.

Parquet: all is not lost!

So, we are looking for the causes of the “waves” and saving this expensive and beautiful coating:

Reason # 1. Parquet laid on the screed too early

Even if it seems to you that the concrete floor is quite ready for installation of a covering - it can turn out to be a huge mistake. Before 28 days, nothing can be done with it - because moisture has not yet completely evaporated. And if you nevertheless laid the parquet, it will absorb the vapor into itself, which will make it swell in some places and it will be as pleasant to walk on it as in the desert with sands. Open and dry immediately.

Reason number 2. Illiterate installation

If you hired a team of irresponsible co-workers for this business instead of professional SUVs, then they may well not leave the necessary clearance. And it is better not to try to solve this problem yourself - call a specialist after all.

Reason number 3. Directly under your parquet - a room with a bath or sauna

So, recently, more and more often in the media there have been complaints and judicial appeals of residents of the most ordinary high-rise buildings, in the cellars of which commercial steam rooms have come from nowhere. And nobody, of course, was worried about the proper vapor barrier of the ceiling: why spend the extra money if the damp floor was not at the enterprising attendant, but at the residents from above. And for those - parquet "waves". And there are two ways out of this situation: by hook or by crook, to kick out basement lovers for steam, or to completely remake dried parquet already on a high-quality substrate with waterproofing and vapor barrier.

Reason number 4. Raw backing

It so happens that the plywood on which you laid the parquet was already brought in raw. You can’t even feel it by touch, but if before that she was standing in a rather damp room, she could not dry out after several hours of installation. And as a result - waves on the floor.

This is due to the fact that different plywood has a different level of moisture resistance. It depends entirely on the brand. But even FC, which is considered moisture resistant, is designed only for small temperature and humidity differences. That is why, when laying parquet, initially order plywood of the FSF brand, high water resistance, which even withstands direct water ingress. Then you will not worry about how this substrate was stored before laying and what will happen to the parquet afterwards. And to determine what kind of plywood you are going to buy, it is easy by the marking applied to each sheet.

“Stone Sea”: we solve problems with screed

You will be surprised, but even the concrete floor will go “waves”. Moreover, by the nature of the "camels" that appeared, one can determine the reason:

- Ripples are a shallow wave after a vibrating rail.

- Wide pits and lenses - local lowering of the floor level.

- Wave swings are repeating smooth changes in the level of the floor surface.

- Bursts - local increase in sex. The point is in the bottom of the floor.

Ways to correct the waves on such a floor: screed, milling, grinding and filling.

"Treat" linoleum: a syringe and skirting boards

So, by means of exclusion, look for the reason why your yesterday, high-quality and perfectly even linoleum "pleased" with the waves:

Reason # 1. There were styling errors

For example, they forgot or, unknowingly, did not leave a gap between the walls and the linoleum, or this distance was insufficient. And each room has its own air humidity, and if you brought linoleum packed in cellophane directly from the store, and immediately secured it with baseboards, it will lie flat, but in the morning this dry material will adapt and expand. If there is a gap against the walls, it will rush there and nothing will happen; if not, it will go “in waves."

Here is a video about the correct installation:

What to do? Check the mounting of the skirting board. If necessary, simply reinstall it so that there is sufficient clearance between it and the floor. And so that the baseboard itself does not press the coating too much.

Reason number 2. Case in glue quality

If you did not fasten linoleum to a special adhesive tape, lay it directly on glue - the reason may be part of the latter. Make a small cross-shaped incision - perhaps you completely missed this area when you applied the glue? Then correct the situation.

First try to solve the problem locally: just pierce the "hump" with a regular syringe and try to draw out the air. Then, in the same hole, pump a little glue and squeeze it well. In more detail - in the photo of the instruction:

Reason number 3. Extreme conditions

Not so long ago there were serious changes in temperature and humidity? You can say goodbye to this unreliable cover at all.

Reason number 4. Too aggressive chemicals in the water for wet cleaning

In simple terms, they overdid it with chemistry and cleanliness. Chemistry does not cause “waves," but it weakens the structure of the coating itself and it deforms more easily. Just check according to the instructions that came with linoleum, what specifically the manufacturer allows him to clean.

Reason number 5. Incorrect mastic applied

It’s necessary to open a little, paint over dry places and smooth linoleum well, laying the load on it. But if everything was processed correctly with the mastic and you personally controlled the process, then just puncture the swollen place with a syringe, pump out air, then put the paper and iron this place as indicated in the photo. What for? The heated mastic again has adhesive ability.

But if the waves are too big, and after pumping out the air you have to fiddle with the iron for too long, put in these places bags of hot sand. If you also have to fiddle with the syringe for a long time, then remove all the skirting boards and expel the air using a long board. But it is impossible to leave “waves”, even small ones: in these places the coating will wear out record fast.

Reason # 6. New linoleum on the old

Yes, do it and quite often: a good substrate in the end, no glue needed, heat. But such "experts" forget that the old linoleum deteriorates even more over time, and, if left without air, it can become completely wrinkled. What the “camels" of the new coating signal about. If the situation is just this - urgently remove both coatings, lay the same gypsum boards and lay new linoleum only on them.

Reason number 7. Change storage conditions

It also happens that after a firm gluing of linoleum to plywood, the next day the coating goes in waves. This is a sure sign that linoleum itself had been stored for a long time in a dry and cold place, and began to straighten out in a wetter and warmer room. Here you need to act quickly until the glue has finally polymerized - remove and re-glue.

By the way, it is also necessary to leave technological gaps between the plywood sheets, otherwise it may swell even under the surface of a simple adhesive diluted in water.

Reason number 8. Permanent deformation

And now - a separate note on the permanent deformation. So, in the technical documentation it is indicated by the symbol "P". We can say that this is something like the memory of synthetic material, expressed in the ability to maintain its original shape. For example, for linoleum, a high degree of this residual deformation is “waves” in the future that you will smooth and tedious for a long time. And this value ranges from 0 to 4, and “2” is a perfectly acceptable indicator for residential construction. That is why we recommend you such prevention of "waves" on linoleum:

- Order this coating in large bays.

- Try to bend or break linoleum as little as possible.

- Find out the date of manufacture of this coating. The older it is, the higher will be its permanent deformation, and therefore do not even consider stale material.

- Look at the natural shrinkage parameter of linoleum - it should be no more than 1 cm per 5 meters in length.

And finally, look at the meaning of “C” on the label. You need C2, the golden mean. This parameter indicates the resistance of the laminate to chemicals. It's about the same wet cleaning.

Knowing all these subtleties, you can easily solve such problems!

1 comment