Waterproofing the bathroom: optimal methods and schemes of the device

Bathroom - a room with a specific operating mode, accelerating the destruction of building materials and furnishings. Condensate that has appeared due to temperature fluctuations, steam, splashes, accidentally spilled or escaping water from the tap constantly attack the lining, "make their way" into the technological seams. Moisture accumulated under the tiled finish, in the joining lines of structures, in the pipe passage areas, gives life to colonies of bacteria and fungi. The results of the vital activity of microorganisms destroy walls, floors, ceilings, poison hosts with toxins. To forget about the horrors of the described catastrophic picture will help waterproofing the bathroom, for which you need to choose the right material and technology for creating a protective barrier.

Content

Materials for creating a water-repellent barrier

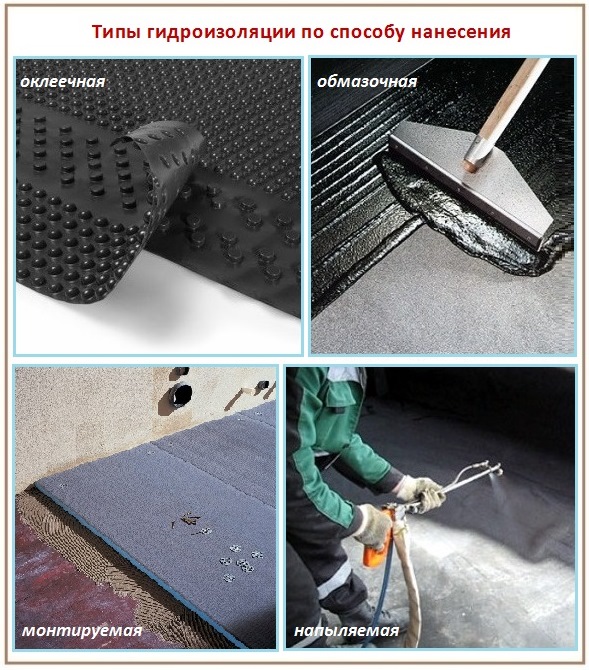

Over hundreds of years of stubborn confrontation with water and its destructive power, mankind has come up with many effective protective schemes, the number of which is replenished with stable regularity. Now in the arsenal of builders and owners of residential suburban and urban residential facilities are:

- panels and plates for the installation of water-repellent cladding;

- the built-up and sticking flexible materials forming a moisture protective cover;

- painting compounds and coating paste-like mixtures, enveloping the treated surface with a waterproofing layer with a thickness of a few tenths to 1.5 cm;

- sprayed coatings that create a foam-cement or foam barrier in the way of water;

- waterproofing plaster, at the same time leveling the walls;

- polymer fill and cement-sand screedenriched with hydrophobic components and fiber for reinforcement;

- impregnations and injections that change the structure of porous building materials, thereby increasing moisture protection properties and strength.

Depending on the technical specifics of the facility whose waterproofing is to be built, choose the type of one or two materials that work perfectly in a pair. It is not realistic to determine what type of waterproofing products and the method of their application will be the optimal solution. However:

- we will take into account that for the protection of hygienic rooms and bathrooms does not require unnecessarily powerful insulation, as for foundations;

- remember that the bathroom will be waterproofed with your own hands, which means that it is desirable that the technology of the device be extremely simple;

- calculate the approximate costs, and ...

Comparing the builder’s own skills with the possibility of implementing complex schemes, and financial savings with the possibility of buying expensive materials, we will focus on two simplest and cheapest methods. This is a coating and pasting. To carry out waterproofing by coating and pasting, a wide variety of finished products are produced that differ in composition, price and application technology. Here, among them, it is necessary to determine the appropriate option, but only after a decision has been made on the upcoming work front.

What is the best way to waterproof a bathroom?

There are no less options than commercially available waterproofing materials.However, numerous variations on the topic under study are based on three fundamental “whales” that determine the zone and area of the forthcoming treatment.

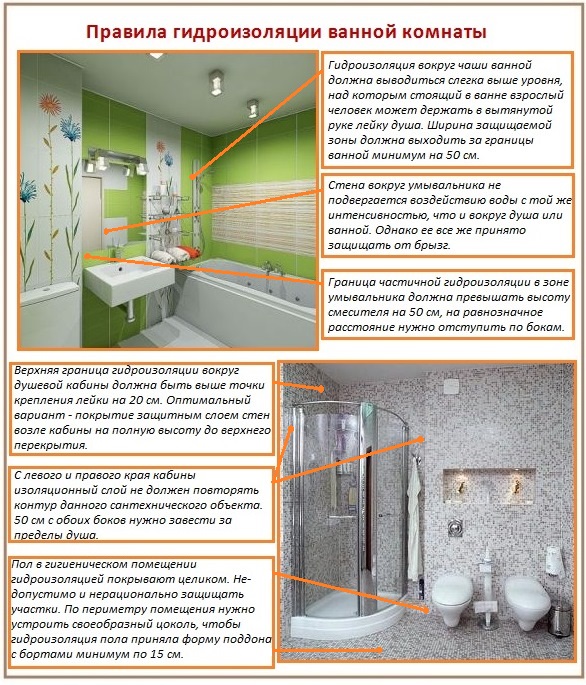

You can protect your bathroom from exposure to water:

- only gender, i.e. cover with an insulating layer only a horizontal surface with the formation of low sides on the walls;

- floor and areas around the bathroom, sink, shower cubicle and other plumbing fixtures;

- the floor and walls as a whole with the complete processing of partitions in height.

Ceiling processing may be added to the last of these schemes, but its production is automatically associated with decoration. Those. staining with a water-repellent emulsion, whitening with a composition with water repellents or the installation of a stretch ceiling system deliberately prevent the effects of steam and condensate on the upper floor.

Attention. Any of the existing methods of waterproofing protection is associated with the mandatory processing of weakened areas: joints of joining structures, panels, blocks, plates, temperature indents along the perimeter, as well as with insulation of the holes through which communications pass.

The need for an early decision on where and how to waterproof the bathroom is dictated by the choice of the method of constructing a water-repellent barrier, because one and the same material is applied differently on horizontal and vertical planes. Before purchasing, you need to find out which method is easier to implement. Before you buy, you should decide which is more important: labor costs or saving, because you have to tinker with the budget scheme, and you have to pay a decent price for the easy way to use the device. And for the right choice you need information.

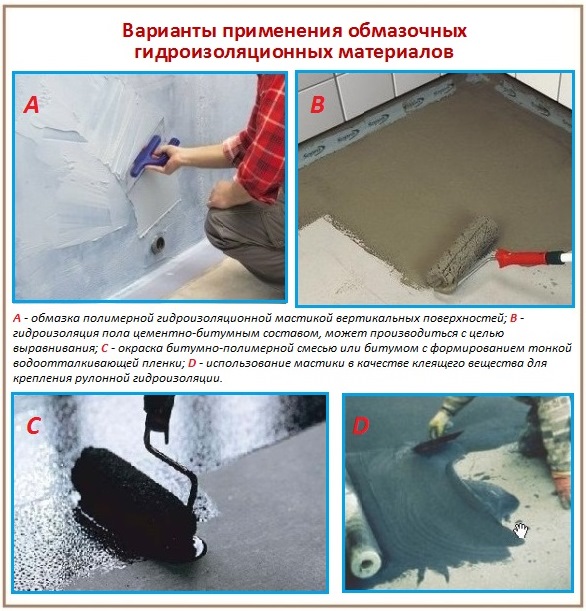

Waterproofing by coating

Based on the name of the group of materials, it is possible to draw a well-founded conclusion about the application method, which also includes waterproofing coatings. It is clear that the consistency of the insulating mass determines the technology of its application and limits the scope of application. The choice of composition depends on the quality and technical characteristics of the treated surface.

The family of waterproofing compounds of the coating type includes:

- Paint waterproofing, forming a thin film coating on the surface to be protected. These include bitumen diluted to a liquid state, similar mastic, water-repellent paints and varnishes, designed to protect structures made of wood and metal. They are applied in two layers with a roller or brush on the walls, and are simply poured onto the floor and distributed by a squeegee scraper.

- Proven by many years of practice, bituminous mastics, pasty mixtures based on oxidized bitumen with modifying additives that increase strength, elasticity, eliminate toxicity. Apply to cement, concrete, cement-sand horizontal structures with a spatula in one or more layers.

Funds belonging to the group of coating waterproofing are mainly used if the bathroom has yet to be filled with screed. They form a continuous seamless film or layer throughout the treated area, which is their most important advantage.

Cement-based waterproofing coating pastes can replace conventional screed varieties. Therefore, there are no high requirements for preparing a draft base before applying them. In addition to compulsory priming, made in order to strengthen the weak upper layers and optimize adhesion.

Tip. Waterproofing pastes with bitumen content, as well as enriched with acrylic, rubber, silicone mastics, treat a dry surface. In order for the moisture to evaporate, it is recommended not to use the bathrooms for at least three days before the installation of water-repellent protection.

Often, mastic is used as an adhesive for the further installation of rolled or sheet waterproofing. In such situations, the thickness of the coating determines the quality of preparation of the base. There should not be significant differences in elevations; deviations of 3 or 4 mm are permissible in a 2-meter section, as after applying the mastic, the differences should not be 2 mm in the same area.

General principles of waterproofing

After thorough cleaning of the insulated base from dust, residues of coloring substances, oils and other debris, cracks are repaired if necessary, then:

- Sutures are sewn into 2 cm along the lines of joining of plates, blocks, panels, the line connecting walls with ceilings.

- The longitudinal grooves made are degreased.

- A self-adhesive waterproofing cord is laid in the formed gates, as well as in the temperature gaps of the floating floors, so that it is completely immersed in the groove-groove.

- A sealing tape is glued on top of the cord to the mastic or solvent, depending on the manufacturer's instructions.

- The floor and planned areas are coated with a leveling plaster and screed.

Instead of a cord laid in the strobes, you can use a silicone mass, sold in a tube with a metering nozzle. The embroidered grooves must be filled with a mass continuously, the excess silicone compound after filling is cut off with a spatula.

Important. The intersections of ceilings, partitions and load-bearing walls with pipelines are poured with bitumen before waterproofing by gluing or coating and again after all operations are completed.

Gluing waterproofing device

On the protected surface, gluing water-repellent options are fused with preliminary heating by a gas burner or glued. Bonding is carried out using mastic recommended by the manufacturer of the polymer glue or adhesive coating applied to the back surface of the roll or sheet. Elements of the created continuous coating are overlapped, joints are putty or glued with mastic used for processing the rough foundation.

The oldest representatives of roll materials are the well-known ruberoid, roofing and glassine. Insulated studded membranes, which are installed if necessary to ensure steam output and prevent the penetration of moisture, for example, onto wooden floors, are persistently superseding them. There is a roll waterproofing that does not allow moisture or steam.

Structurally, pasting agents of the latest generation are a multilayer flexible material with a base of fiberglass, polyester or glass-roofing material. On both sides of the base there are layers of polymer binders. In order for the gluing waterproofing to be rolled up, convenient for storage and transportation, a protective film of polyethylene is applied over the working polymer-binding layers.

Attractive quality of pasting - budget price, negative sides:

- the need for preliminary measurements and cutting;

- thorough preparation of the base; height differences of 2 mm within 2 m are not allowed;

- application of a torch for the built-up type;

- the difficulty of working in small rooms;

- laborious laying process with thorough leveling of corners and floor panels.

Sticking waterproofing is quite difficult, the material can be damaged by careless movement, break through when forming a trowel with an angle, and the fused variant is overheated to a gap. But the masters who want to save money cannot be stopped by listing the complications; it is better to familiarize themselves with the technology and rules for waterproofing the bathroom by pasting.

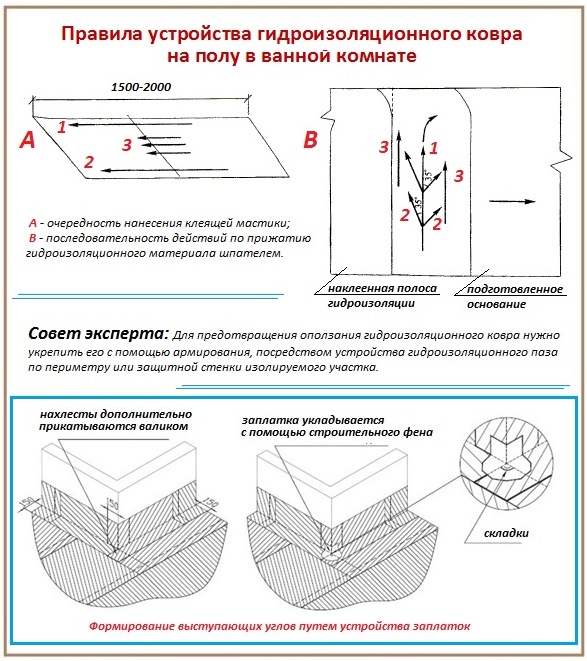

Specificity of the device for gluing waterproofing

The task is greatly simplified if the home foreman acquires self-adhesive material, from the back of which you just need to separate the protective polyethylene sheath, then glue it and roll it with a heavy roller.

Do not forget that before the construction of pasting protection:

- the walls and floor must be leveled and wait for the complete loss of moisture by the screed and plaster;

- remove dust and dust, preferably with a vacuum cleaner;

- Coat twice with soil;

- waterproofing butt joints;

- apply polymer glue or waterproofing mastic if necessary.

Roll material is cut according to the dimensions made in advance. It is recommended to previously withstand cut strips or sheets in the unfolded state for about a day.

The number of layers created by the roll material depends on the planned degree of reliability of the waterproofing. To protect the walls and floor in the bathroom, 2 layers are enough, but their number can reach 5.

Tip. The stripes lying for a day in the unfolded state for the convenience of gluing, it is better to roll it again into a non-tight roll inside out. As you stick it will need to be gradually rolled out.

When creating a multilayer insulating carpet, we will alternate the adhesive with the carpet created from the strips. Be sure to take into account that they were cut with an allowance for the formation of the sides, and we do not glue those 100-120 for the bathroom area or 10-15 cm for the floor bowl from both edges of the cut panel:

- the first cut strip is laid in a way convenient for the master. The place of commencement of work does not matter, because You can navigate through the roll waterproofing immediately after gluing;

- the edges are coated with mastic and lay down the next strip with an overlap, the value of which should not reach, and even more so exceed 20 cm;

- after the installation of a continuous sheet on the floor, allowances for the sides of the floor or for the protective zone around the bathroom, shower, sink are glued to the walls. Stripes of gluing waterproofing on vertical surfaces begin to glue from the bottom, moving up.

- a mastic or an adhesive component is again applied on top of the laid waterproofing layer;

- the strips of the second layer are placed across the previous one, leaving the stocks not glued. After fixing these allowances to the walls, a waterproofing bowl will be formed with the sides necessary for protection on all sides.

These are the ways to protect building materials from the negative effects of moisture. If you are not too lazy and build waterproofing protection, the main building materials and decoration will last much longer. You will not need to spend money on repairs, the purchase of new bathroom furniture and the replacement of plumbing. It is not difficult to calculate what will actually be cheaper.

2 comments