Installation of plastic skirting boards: a comparative overview of 3 mounting options

As you know, during the repair and arrangement of any room of insignificant details does not exist. Moreover, sometimes, seemingly secondary elements of the interior, in fact, play a key role in creating the perfect picture. Here's what you think: what is more important flooring or skirting, which are installed last? If you think carefully, it is impossible to give preference - everything should be harmonious. As part of this article, let's look at what constitutes the installation of plastic skirting boards. Why exactly them? Yes, because they are currently the clear sales leaders.

Content

What tools and consumables will I need?

Naturally in the house you need to have a well-equipped set of tools - it will come in handy in many situations. But if you take specifically the installation of this floor element, then at least you should be aware in advance what you will definitely need when installing it:

- Hammer drill or hammer drill (drilling concrete walls).

- An ordinary screwdriver or drill (drilling wooden materials or drywall).

- Cutting machine (grinder) or hacksaw (will significantly reduce the time required to trim parts).

- A set of attachments for a screwdriver or screwdriver.

- Roulette.

Even before buying, you need to calculate not only the number of skirting boards, but also take care of how to fix it correctly. Depending on the mounting option you may need:

- clips for fastening;

- self-tapping screws;

- glue or liquid nails;

- dowels.

Note! As a rule, manufacturers supply baseboards with a standard length of 2.5 m for sale. If the room has walls with large dimensions, then the baseboard will have to be "lengthened", and for this you will need connectors. It is necessary to try to make calculations in such a way that the joints were hidden behind a sofa, a closet, covered with a door, etc.

- Connection profile.

- End cap, end (left).

- End cap, end (right).

- Outside corner.

- Inside corner.

Design features

In the still unforgettable Soviet construction past, the baseboard was usually made of wood, and its entire installation was a banal nailing. Today, for the manufacture of a skirting profile, fiberboard, SDF and, of course, the plastic we are discussing are used. But this does not mean that only professionals know the answer to the question of how to install a plastic baseboard correctly. People without special construction skills can very well cope with this.

Today on the market there are three types of plastic skirting boards:

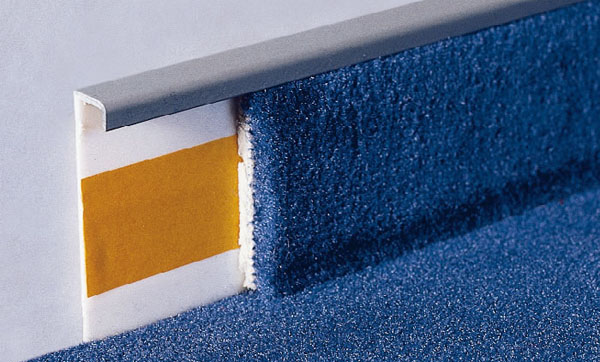

- for carpet and linoleum;

- universal;

- flexible.

The first is L-shaped and with its lower part presses the finishing coating to the base. The groove made in the upper part is used to fasten the edge of the carpet, which is pushed onto the wall. Fastening is carried out using dowels. Visually, the perimeter frame does not differ from the main material, which makes this option elegant and modern.

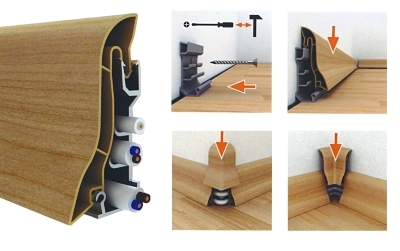

Universal skirting boards have a hollow design and, in turn, are divided into products with internal and external cable channels. The advantage of both of them is the presence of special grooves in which a variety of power and signal cables can be laid. Models with internal cavities are attached to the wall using special brackets, which professional installers call clamps.

Skirting boards of the second type have a channel on the outside, which, after mounting the conductors, is closed with a special plug in the form of a long strip. Thanks to it, the fastening of models with an external cable channel can be performed both with the help of clamps and ordinary dowels - subsequently, the attachment points will be hidden by the same flexible plug.

The advantage of universal plastic skirting boards lies in the fact that they can be removed and reused - you probably know about this from commercials of manufacturers of building materials. But they are silent about the fact that even the most careful dismantling leads to damage to the plastic protrusion on the back of the finishing panel. This happens because the clamps have inwardly curved steel spikes that securely hold the product during operation. When a force is applied, cracks and delaminations of plastic appear in the fastening zone, because of which it will not be possible to reliably fix the element to its old place. There is only one way out of this situation - to move the clamp by a couple of centimeters to the side so that it engages with the undamaged part of the baseboard. After that, the connection will again be reliable and durable.

Flexible skirting board is designed to frame various curved surfaces - flush zones, wall curves, etc. Its installation is carried out on special glue. The disadvantage of such a frame is its one-time use. As a rule, when dismantling the product is damaged and cannot be reused.

Comparison of mounting methods

Plastic baseboards can be fastened in several ways:

- on special mounts;

- on glue;

- just screwing it with screws.

Special equipment - staples

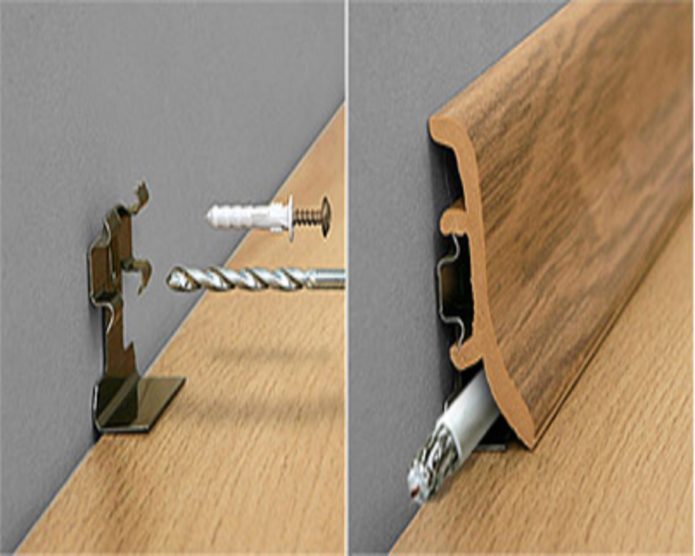

The advantages of this method are that no obvious traces of fasteners are visible, the baseboard is easily dismantled and reinstalled. Although the latter circumstance, advertised by the manufacturer, in practice may not give an ideal implementation. Very often, the skirting board removed from the mount cannot be reinstalled perfectly. Especially when it comes to metal mounts. The disadvantages include the fact that during installation, fasteners require perfect condition of wall and floor surfaces.

Adhesive mount

The main advantage is the visually attractive appearance of the skirting board. Installation in this case is very simple: we lubricate the material of the desired length with glue and press it against the wall. Naturally before installing angles, couplings and plugs. Disadvantages: it is virtually impossible to dismantle without loss of appearance, and in most cases the deformation is critical. High demands on surface quality.

By the way: as a good example, you can take a popular adhesive - “liquid nails”.

Using screws

This method is reliable and cheap. Before attaching the baseboard, you do not need to prepare the abutment surface. The disadvantages of the method: the plinth looks a little rude, and when you complete the installation, more time is spent.

Installation instructions

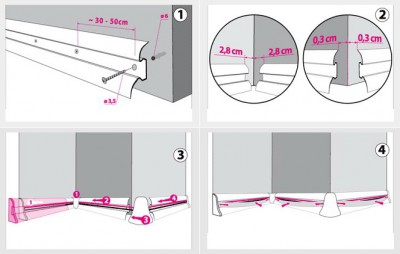

As already briefly noted above, the installation method depends on the design of the skirting board. Consider the simplest and fastest method of fastening using conventional dowels:

- Installation begins from the corner, if necessary, cutting off the bar of the required length.

- Having previously removed the plug, the baseboard is applied to the wall, aligned and made through holes, penetrating into the wall to a distance of 25 mm. The fastener pitch should be from 10 cm in short segments and up to 50 cm if an entire panel with a standard length of 2.5 m is used.

- Dowels are driven into the holes made, after which the plastic frame is fixed with self-tapping screws.

- A suitable additional element is installed on the edge of the mounted strip (inner or outer corner, docking station or end cap), after which they try on and similarly fasten the next panel.

- After the installation of the last element is completed, cables are laid in the inner channel and the structure is closed with a plug.

Installation of the baseboard on the clips begins with the fact that the bar is applied to the wall and determine at what height the fasteners will be. As in the previous case, work is carried out from the corner, placing the first clamp at a distance of about 100 mm. For its fastening, a hole is drilled into which a plastic dowel is inserted. After this, a clip is applied and fastened with a self-tapping screw. The distance between adjacent mounting points is selected depending on the length of the plastic panel - you can follow the same recommendations that we gave for through installation. To attach the baseboard to the clammers, a small force is sufficient to overcome the stiffness of the steel bracket, inside of which there is a protrusion on the back of the finishing panel.

In principle, we have examined all the nuances of installing a plinth profile made of plastic in the framework of this article. But, as you know, it’s better to see it once, so we offer you a familiarization video:

8 comments