Solid wood skirting board: how to choose and install yourself

Wooden flooring, such as solid wood or parquet, requires decent framing. Popular laminated and plastic skirting boards are not an option. Their artificial origin will be noticeable and this will visually reduce the cost of an elite wooden surface. For wooden floors, only a skirting board of the same quality is suitable - massive, made of solid wood. First you need to select it correctly, and then install it. How to do this for a home master? First things first.

Content

Choosing a massive skirting board

Skirting Material

First of all, when inspecting racks with baseboards in the store, pay attention to the wood from which they are made. According to the design rules of a good tone, it is recommended to choose a massive plinth made of the same wood species as the floor covering. In this case, harmony in the room will be ensured even without the presence of good taste and design skills. Therefore, many manufacturers, trying to simplify the choice of consumers, produce the appropriate skirting boards for their products: parquet and solid board. Among these manufacturers I would like to highlight: Komodoor, Parketoff, Stenwood, Magestik floor.

However, interesting effects can be achieved by combining different colors, textures and wood species. Moreover, the range of commercially available skirting boards from the array allows you to experiment.

Popular wood species used for solid skirting boards are:

- Pine is a relatively inexpensive wood with excellent performance. It contains bactericidal substances that prevent rot even in wet rooms (baths, washing, showers). The color of the pine is light yellow, so it can be tinted in any tone.

- Aspen - almost white wood, easy to process. Due to its softness, any baseboard profiles can be cut out of it. Installation in damp rooms is allowed - aspen weakly decays.

- Alder - light, soft breed. Not durable, not moisture resistant. It easily breaks, so when installing skirting boards made of alder, craftsmen advise using screws and not nails. To fasteners did not cause the appearance of dark spots on the surface, use screws with zinc or phosphate coating.

- Walnut is a durable, beautiful material of a brown-gray shade with a clear pattern of fibers. Easy to process, resistant to rot and fungus. Flexible enough, so it can be used to form bent skirtings.

- Oak is an elite wood with a noticeable coarse-fiber structure. The high cost of oak skirting boards is offset by their strength and durability. The natural color is light brown with a greenish tint. The technology of artificial aging, staining, whitening, which allows to give the wood a unique look and unique shade, is often applied to oak products.

- Beech - plastic wood pinkish yellow, very hard. Toning easily imitates beech "under the oak." Beech can be used to make curly and curved skirting boards.

- Mahogany is an expensive material that is durable and decorative. Color - saturated, deep red with a brownish tint.

- Wenge is an exotic breed characterized by a coarse structure with large fibers. The color of the wood varies from golden brown to chocolate and almost black. Wenge flooring and skirting boards are often used for ethnic interiors.

The listed breeds are not a complete list. Wood of pear, cherry, acacia, ash is also used. More exotic options are kempas, merbau, bamboo, rosewood, sapelli.

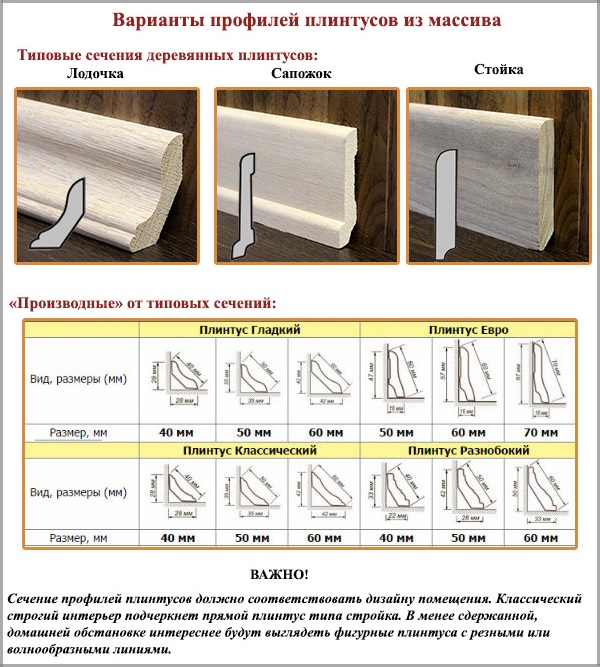

Baseboard shape

The range of modern skirting boards is no longer limited to products with a triangular section, which was practically the only possible a couple of decades ago. The market offers a huge selection of shaped profiles. Typical sections (on the basis of which many improvements have been created) of wooden plinths are as follows:

- stand - a straight section with a rounding at the top;

- boat - a section in the form of a triangle with a wavy rounding;

- boot - section with a shelf at the bottom.

Here's what it looks like:

Types of finishing skirting from solid wood

Massive skirting can be purchased in three versions:

- Varnished - coated with a glossy or semi-gloss layer of varnish, which gives the product shine and a complete look. The varnish emphasizes the color and structure of wood, and also protects it from mechanical damage and moisture.

- Oil-impregnated - without a film on the surface, but with an emphasized structure and fibers. Oil impregnation makes the wood wear-resistant, durable, moisture resistant.

- Uncoated - baseboard polished, prepared for further processing at home.

Uncoated skirting is the most versatile. After installation, it can be varnished, treated with oils, tinted or painted to match the coating.

Important Quality Attributes

Massive skirting is always more expensive than its counterparts from other materials. Therefore, you have the right to demand high quality from the manufacturer. When choosing a skirting board, pay attention to:

- The ends. They should not be charred. This drawback indicates that the baseboard was kept in the oven for a long time and dried out, and this is fraught with the appearance of cracks.

- Surface. High-quality skirting board has a smooth, well-polished surface, without protruding fibers. If all these imperfections are present, the wood is most likely moist and therefore not amenable to grinding. Do not buy such a product! Over time, it will begin to dry out and deform.

- Geometry. All planks in the batch must have the same size and shape. To determine the correspondence, it is enough to dock two arbitrarily selected skirtings with the ends and the rear surface (in length). There should be no noticeable gaps.

- Natural defects - knots, sapwood. The smaller they are, the stronger, denser and more durable the wood. In addition, the presence of many knots negatively affects the aesthetics of the product.

- Matching shades of planks. Sometimes planks in one batch differ from each other in shade. And this can be an unpleasant discovery if it is necessary to dock elements in corners where this discrepancy will be especially noticeable.

- Existence of a cap for masking of fastenings. This item is optional but useful. The stub extends along the product in the center, closing the caps of the fasteners.

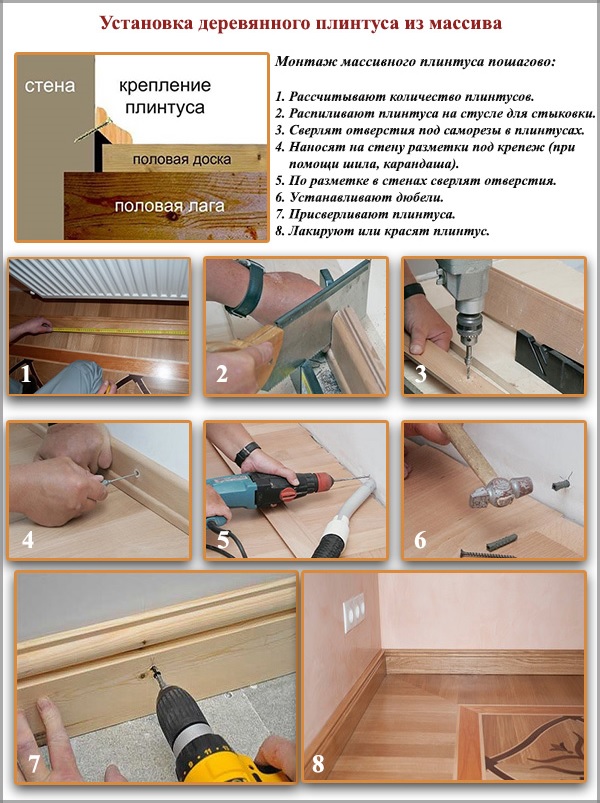

How to install a baseboard from an array?

Installing a massive skirting board will not take much time, but it will require accuracy. The following materials and tools will be needed:

- wood hacksaw;

- roulette;

- miter box;

- building corner;

- electric drill;

- screwdriver;

- screws, long nails, dowels.

Step 1. The calculation of the number of skirting boards (in pieces)

To find out the number of plinth planks, simple calculations are performed. Measure the perimeter of the room, with the exception of the length of the doorways. The result is divided by the length of the selected type of skirting (standard length 2.5 m), rounded to a larger integer. If there are a lot of corners in the room, which implies a large number of cuts and joints, the skirting board is taken with a margin of 1-2 pcs.

Step # 2. Preparation of skirting boards for alignment and docking in corners

Using a tape measure, measure the length of the wall from one corner to another. Transfer this size to the baseboard, mark the place of cut.

In the corners, to obtain slices at 45 °, a miter box is used. It is fixed on a stool, table or other flat surface through the mounting holes available on the bed.

The cut of corner elements is performed as follows:

- The baseboard is installed in the body of the miter box in the same position in which it will be attached to the wall. That is, not flat, but on the rib. Some models of miter boxes are equipped with special clamps that allow you to fix the baseboard during cutting. This ensures that the cut is smooth and the joint is perfect, without gaps.

- Set the hacksaw blade to the desired position and perform a cut. The next cut is done on the second baseboard, which will dock with the first.

- Skirting boards are combined in the corner. If there is a gap between them, then the sections are finalized with the help of a miter box and a hacksaw. Or using sandpaper mounted on a bar. It should be remembered that it is unlikely that an ideal joint will be achieved. Therefore, a gap of up to 0.5-0.7 mm is considered acceptable, which can be filled with putty or sealant to match the tone of wood.

Not always with one plinth you can cover the length of the entire wall. Sometimes you have to use 2-3 skirting boards that combine in a straight line. There is no unified technology for joining massive skirtings. You can combine their ends directly or at an angle, but then you have to use a hacksaw and a miter box to get even cuts.

Step # 3. Drilling holes for fasteners

Usually massive skirting boards are mounted on self-tapping screws or finishing nails. Mounting is done to the wall.

To begin with, on the baseboards mark the places of fastening of screws with a pitch of about 50-80 cm, at a height of 20 mm from the bottom edge. Drill holes, perform their countersinking using a cone-shaped nozzle on a screwdriver. So get sweatshirts - small extensions to deepen the heads of the screws. Otherwise, the hats will rise above the surface of the plinth and reduce their decorative appearance.

Step # 4. Fixing the baseboard to the wall

Plinth is applied to the wall and through the existing holes mark the places of fasteners on it. According to the marking, holes with the desired diameter are drilled and plastic dowels are immediately driven in. Screws are screwed into the dowels, firmly connecting the baseboard to the wall.

Instead of self-tapping screws, you can use thin finishing nails. The fixing technology remains unchanged, but instead of plastic dowels, you need to take wooden ones. The use of nails allows you to get an almost imperceptible fastening, thanks to small hats. At the same time, wooden dowels are not as stable as plastic, and can fall out of the wall. Especially if its surface is drywall or has pronounced irregularities.

Step # 5. Masking mounts and joints

Joints and fasteners (sweat) are sealed with sealants, hard putties on wood or wax. After grinding the hardened composition, the skirting board can be varnished or coated with paint.

Video example of installation work

In order to better understand the principle of installing a wooden skirting board, see the video story:

2 comments