Cleansing and protective products for linoleum: types and methods of application

The longevity of linoleum directly depends on competent and regular care for it. PVC coatings need periodic (daily) cleaning, applying protective coatings and, as necessary, general cleaning with the involvement of cleaning equipment. All these events are carried out using specialized tools: cleaners, strippers, polishes (varnishes, mastics, polymer emulsions). Some of them are used to clean coatings, others - to create a strong protective film on the surface.

Content

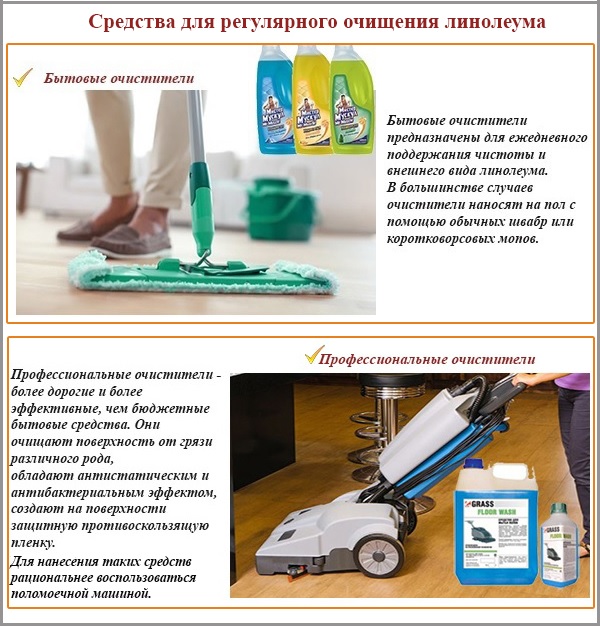

Daily Cleaners - Cleaners

Daily linoleum care is a normal wet cleaning. Most owners of PVC coatings and marmoleums (natural linoleums) prefer to wash them with clean water without using special tools. However, the effectiveness of such cleaning is not always at the proper level. Ordinary water is not able to wash away many pollutants, which, remaining on the coating, eat into it, become the cause of microscopic scratches. As a result, the top layer of linoleum undergoes abrasion, its appearance worsens.

In order not only to clean the surface of linoleum, but also to provide it with micro protection against damage, special cleaning agents are added to the washing water. They dissolve the smallest particles of dirt that have fallen into the pores of linoleum, and also strengthen (or create!) Its protective layer. In other words, after applying the cleaners, the coating not only becomes clean, but also receives protection from the penetration and adhesion of contaminants (in the form of a microfilm on the surface). The protective layer may also have a noticeable decorative gloss and anti-slip properties.

When choosing a cleaner, special attention is paid to its purpose. There are universal budget funds that are suitable for processing floors from different materials. For example, Mr. Proper, Glorix, Mr. Muscle. They should not be expected to have a special effect, their purpose is exclusively the elimination of fresh, not soiled pollution. To care for expensive linoleums, preference should be given to specialized cleaners, for example, from the line of products Mellerud, Wa-Lin, Econa-Konzentrat, Forbo (888,891).

Particular attention should be paid to the choice of a cleaner for natural linoleum. On the product label must necessarily indicate the possibility of its application to the marmoleum. The fact is that this material is unstable to substances with solvent properties, acids and alkalis. Therefore, cleaners for marmoleum should be gentle with a minimum content of aggressive substances. Among such funds can be identified Forbo (888,891), Li-Ex, Procur Konzentrat.

Many (especially professional) cleaners are suitable not only for daily cleaning, but also for periodic deep cleaning of linoleum. In this case, a more concentrated solution of the agent is used.

All cleaning agents are concentrates, that is, require dilution in water. The concentration of the finished solution depends on the product used and the percentage of cleaning agents in it. For example, for daily cleaning, it is enough to dilute 1 cap of Forbo 888 concentrate in 10-15 liters of water.

To wash linoleum with the resulting solution is most effective with a mop with a mop (nozzle) of microfiber. Wipe the floor with a cleaning solution, wait for it to dry. Some cleaners require a thorough rinse with clean water.

Means for deep cleaning (washing) - strippers

To maintain the cleanliness of linoleum in an apartment or a small private house, it is enough to carry out regular cleaning with ordinary cleaners. But, even in this case, after 1-2 years it will be seen that the coating has already worn out. In offices, restaurants, hospitals, shopping centers, the period of visual aging of linoleum occurs even earlier. To "rejuvenate" the coating, deep cleaning products are used - strippers. They are designed to dissolve deeply ingrained contaminants, remove scratches and old layers of worn polishes (mastics).

Most strippers are aggressive alkaline solutions. Strippers with a pH level in the range of 11-15 are used to clean PVC linoleums. For example, Crowbar (from Butchers) has a pH of 14.1. Strippers for natural linoleum are more gentle, their pH should not exceed 10. For example, Lino (from Berner) in the working solution has a pH of 10, and the neutral agent "InterChem 105" has a pH of 7.

Deep cleaning with a stripper is called blurring or stripping. At the same time, a stripper is applied to the surface to be cleaned, and then it is treated with disk machines. Therefore, deep cleaning is usually entrusted to cleaning companies, which have specialized equipment in their arsenal.

Cleaning with strippers is carried out in several stages:

1. The concentrated stripper is dissolved in cold water (it is not recommended to use hot water because of the possible evaporation of the volatiles of the stripper and a decrease in the efficiency of the solution). Depending on the composition of the stripper and the desired cleaning intensity, the concentration of the product in water may be different. For example, Time Buster (from Butchers) requires dissolution in water at a concentration of 1: 1 - 1: 3 - for intensive cleaning, at a concentration of 1: 6 -1: 10 - for medium cleaning (normal), at a concentration of 1:10 - for cleaning marmoleum.

In addition to concentrates, there are strippers ready for use. For example, the stripper "InterChem 104" is supplied in a bottle with a spray; its purpose is to deeply clean the surface in hard-to-reach places (near walls and baseboards, under batteries).

2. Conduct a stripper compatibility test with the surface being cleaned. To do this, wash on a small surface of linoleum. It is advisable that this be a place that will be further covered by furniture.

Test washing is carried out as follows. In a selected area of linoleum, using a mop, distribute the stripper solution. Leave it to soak into the surface for 15 minutes. Next, perform mechanical processing and rinse off the product with water. They expect complete drying of linoleum and evaluate the result. If after the operations performed, the coating discolored or other uncharacteristic changes appeared on it, then the stripper used is not suitable. It is necessary to use another. If everything is fine, then perform the next stage of washing.

3. Apply the solution to linoleum with a rope mop of the Kentucky type. The product is applied abundantly, wetting the surface with it. The area for application (if processing is carried out by one master) should not exceed 20-25 m2.

4. The stripper solution is kept on the floor for 10-15 minutes. At this time, manual machining is carried out (using brush-irons, hand pads) in hard-to-reach areas of the coating. For example, along the skirting boards, under the batteries - where machining with a rotary machine is difficult.

5. After the exposure time, the floor is treated with a rotary machine with a pad. The color of the pad is chosen depending on the desired degree of grinding. The darker the pad, the harder it is, respectively, the rougher the grinding it performs.The most suitable for linoleum are red, green and blue pads.

6. The stripper solution is removed from the surface of the drainage system.

7. Water is abundantly applied to the surface of linoleum, wait 2-3 minutes and all the water is collected by a suction pump, scrubber drier or manually - using a mop. Then the coating is dried. If necessary, accelerate the drying, wipe the floor with a dry clean mop.

Stripping is a procedure that is part of the general cleaning of linoleum offered by cleaning companies. Washing is not done on its own. At its end, linoleum is always coated with polishes.

Protective agents - polishes (mastics, varnishes, polymers, emulsions)

In order to protect linoleum from premature wear and excessive pollution, use protective compounds - polishes. They are supplied in liquid form (in cans and bottles) and, after application to the floor surface, form a protective film. In addition to increasing the wear resistance of linoleum, such a film improves its decorative properties, giving shine. InterChem 301, InterChem 305, and InterChem 306 polishes have a deep glossy shine. InterChem 302 coating makes linoleum semi-matt, and InterChem 303 - matte, with a muted satin sheen.

It should be noted that protective equipment often has different names, although in all cases the same type of coating is implied. Often found names of polishes - mastics, varnishes, waxes, polymers, emulsions. All this is one and the same.

The traditional composition of linoleum polishing polishes: aqueous dispersions of acrylic copolymers, aqueous emulsions of waxes (natural or synthetic), coalescents, additional components (to smooth the surface, reduce foaming) and preservatives. Other substances can be introduced into the composition, for example, polyurethane, which makes linoleum practically “bulk floors”. Polyurethane gives additional gloss to the coating, increases (compared with conventional polishes) wear resistance. However, polishes with polyurethane also have a drawback - after the end of the operational period they are very difficult to wash off from the coating.

There are two types of polishes: non-metallic and metallized. Zinc ions are additionally introduced into the composition of metallized polishes, enhancing the resistance and gloss of the coating. Non-metallic polishes do not have “metallic” protection, therefore they wear out faster. At the same time, such compositions are cheaper, they are easier to wash off the coating, it is easier to care for them. The metallized coating makes linoleum almost “impenetrable”, but requires special application and washing technology. Such protection can be applied to linoleum in all rooms, except those where there is a lot of humidity (kitchen, bathrooms). When exposed to water (for example, with high humidity, water entering the coating and the appearance of standing puddles), the metallized coating becomes cloudy and loses its operational properties.

Method of applying polish to linoleum:

1. Linoleum is thoroughly cleaned, it is recommended to do this with strippers, that is, perform deep cleaning. The fact is that any contamination on linoleum will lead to poor adhesion of the protective layer of polish, which is fraught with delamination. The adhesion worsen and the old layers of polishes, so they also must be removed by strippers.

It should be cleaned not only previously in use, but also just laid, new coatings. On modern linoleums, manufacturers often leave a microscopic protective layer (so that the material does not stick together, being in rolls). And it must be removed before applying a new layer of polish to avoid problems with adhesion.

2. Linoleum is washed with clean water to remove the alkaline composition of strippers.

3. Polishing fluid from the canister (or other containers) is poured onto the floor in parallel “tracks”. The distance between them is 1.5-2 m.If the width of the room is less than 2 m, then pour one "path" in the center. To form the first protective layer of polish, the “paths” are placed parallel to the direction of the incident rays from the main light source (usually this is the largest window).

4. The polish is distributed across the entire floor perpendicular to the direction of the “tracks” using a short-haired mop (50 cm wide) of microfiber. Distribution is carried out by the figure “lying eight”, without taking the mop off the floor.

5. After drying the first layer of polish (15-30 minutes), apply the second layer. In this case, the “tracks” are poured across the direction of the “tracks” of the first layer. Thus, after distribution by the mop, it turns out that the polish layers are applied perpendicular to each other.

It should be noted that the cross application method is not always used. For example, in narrow long corridors, perpendicular layers may be inconvenient. Then all layers are applied in one direction. The “paths” are poured along the corridor, and then distributed with short movements (along the width of the corridor) of the “lying eight” figure.

6. Using the same system, the remaining layers of polish are applied. To form effective protection, they should be from 2 to 6 (total). The number of layers required depends on the composition of the particular polish and the size of its “dry residue”. By "dry residue" is meant the ratio of the mass of non-volatile substances (those that will form the protective film) to the total mass of the mastic.

Example: if the polish has a dry residue of 25, this means that when the substance dries, only 25% of its composition will remain on the surface of linoleum and form a protective film, the remaining 75% will evaporate. For example, for two different polishes, the values of the "dry residue" differ by 2 times. Accordingly, when a protective film of the same thickness is formed with their help, 2 times more layers of that polish will be applied, the “dry residue” of which is less.

Complete drying of the protective layer of polish occurs after 8-10 hours. During this period, the surface should not be stressed (it is forbidden to walk and install furniture on linoleum). When applying and drying polishes, it is necessary that certain climatic conditions are observed in the room: the absence of drafts and direct sunlight.

The most common mistakes made in polymer application technology:

- Insufficient cleaning of the linoleum surface before applying the polymer. Cleaning measures may include deep cleaning processes (using strippers or concentrated cleaners), regular cleaning (using daily cleaners). In any case, all cleaners are chemical substances, most of them have alkali in their composition. Therefore, before applying the polish, all chemicals must be washed off the surface with clean water. If necessary, wash 2 times. In case of poor floor washing, the polymer layer may become cloudy, acquire a grayish tint or peel off from the base.

- Drying the applied polymer with a draft. Such an error leads to peeling of the protective layer in the form of strips.

- Application of a subsequent polymer layer onto an insufficiently dried previous layer. In this case, the polymer film will be uneven, cloudy. On average, the drying of the layer lasts 15-30 minutes. However, this period can both be shortened and lengthened, depending on air humidity and room temperature. To find out if the polish has dried or not, just touch the coating with the back of your hand. If the coating is sticky to the touch, it means it has not dried out yet and you need to wait again.

The application of polishes is the final stage of the general cleaning of linoleum. After that, it is enough to regularly wash the coating with one of the selected (ideally - professional) cleaners. Then linoleum will remain in its original fresh state for many years.

2 comments