How to quietly glue the joints of linoleum: tricks from professionals

Despite the fact that the market has a huge variety of flooring, linoleum does not give up its position. He is preferred by people of various incomes and aesthetic tastes, and everyone finds the best option for himself. To summarize, linoleum is a rolled polymer material for flooring. Its scope is extremely wide, and a wide range of species, characteristics and sizes are also available. In order for the flooring from linoleum to look just fine, you need to correctly calculate its amount and choose such a width of the material to do without joints or minimize their presence. If this is impossible, then you should not be upset - there are methods that will help make the seams almost invisible. Let's try to figure out how to glue linoleum so that even a trace from the joints is not left. Is it possible? Maybe.

Today, several methods are known and widely used for discreetly connecting the paintings to each other. To create a beautiful, tight and reliable seam, linoleum hot or cold welding is most often used.

Hot or cold welding?

The answer to this question depends on:

- the type of linoleum (so, for the commercial version of the coating, you can use both hot and cold welding), and to connect the edges of household linoleum - only cold, since such a coating will not withstand high temperatures;

- on the complexity of the configuration of the seam (for example, when performing all kinds of applications with complex contours on linoleum, the seam will be faster, easier and more accurate using cold welding).

Hot welding of linoleum joints

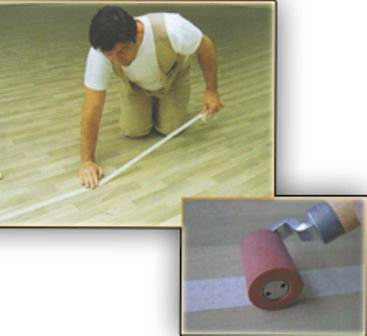

The use of hot welding of linoleum joints allows you to get a very durable seam. Spend it after the coating is already firmly glued to the floor, using a special cord made from linoleum, and a device for heating it:

- After the linoleum is laid with a minimum gap between the canvases, a chisel or other device, a groove (small groove) for the cord is cut along the entire length of the joint.

- Thoroughly clean the junction of dust and debris.

- The selected cord is tucked into a welding gun-dryer, which is then plugged into the mains.

- Under the influence of warm air, linoleum and cord soften, melt and firmly connect.

- Then the master carefully cuts off the excess part of the cord protruding above the surface.

Despite the apparent ease of implementation, this procedure requires not only special devices, but also a certain skill that allows you to perform it efficiently. For independent execution, cold welding is more suitable.

Cold welding of linoleum joints

Cold welding is a liquid and quick-drying special glue, which is sold in tubes with a needle tip, which serves for deeper penetration of the glue into the seam and allows reliable bonding of linoleum joints. Bonding takes place at the molecular level, which provides an amazing strength of the joints of linens of household, commercial, semi-commercial linoleum. Especially relevant for foam-based coatings, since hot welding is contraindicated.

Its main advantages:

- it is quite possible to cope with the work without the involvement of masters;

- Ideal for home use

- can be used not only for laying flooring, but also for its repair.

The most commonly used glue is of two types: A and C. The difference between them in consistency. Type C glue is much thicker, it is used for gluing joints of old linoleum, which can be a few millimeters wide. Filling the gap, it is possible to obtain a durable seam, which does not allow the canvases to diverge in the future, and fastens them tightly. Type A is suitable for “freshly laid” linoleum. This glue “works” a little differently: it actually melts, “welds” the edges of linoleum.

Cold welding with type A glue should be carried out with gloves and with the window open. The seam is thoroughly cleaned with a vacuum cleaner from debris and dust. Masking tape is glued to the edges of the panels, which will protect the part of linoleum that does not need to be melted. Carefully cut the tape over the joint of the canvases. Apply glue by pressing the needle deep into the seam and slightly pressing on the tube so that the glue protrudes approximately 4 mm above the surface. After 15 minutes, you can remove the tape. Cold welding with type C glue follows approximately the same pattern. True, you can do without tape, as the glue is thick, it will not creep.

If during repair it became necessary to dock linoleum canvases, this is not a reason to be upset. For such purposes, cold and hot welding of linoleum is most often used. The latter option is more suitable for commercial coating, it requires special equipment and skills, so it is extremely rare to use it in everyday life, but cold welding is used more often, because the technology for its implementation is simple and affordable. With correctly performed cold welding, an almost imperceptible, neat seam is obtained that does not spoil the appearance of linoleum.

2 comments