Basic methods for testing concrete for strength

The quality of reinforced concrete structures determines the strength of concrete. The safety and life of a multi-storey building and other concrete products depends on this parameter.

The strength of concrete can be determined by the brand of cement, which was used during construction. For example, if cement is grade 400, then, accordingly, the maximum load that concrete products built from this material can withstand is 400 kg per square centimeter.

But there are other examples of testing concrete for strength.

Destructive

This is the oldest, but the most reliable method of testing multi-storey buildings. The procedure consists of testing the constructed structure to withstand a 9-point tremor.

In other embodiments, a control sample is taken that has not yet hardened, wait until it finds the desired hardness and reliability, and by means of special devices they are tested for strength.

Ultrasonic testing

Verification procedures include ultrasound testing. The procedure consists in arranging the sensors on different sides to record the passage of ultrasound through concrete. Another type of ultrasonic testing is the location of the same devices on one side. Similarly, the surface strength of a material is determined.

Devices are used to determine the strength of the material, as well as for flaw detection, determination of depth. Ultrasonic testing is limited. They can not be used for high strength concrete products. Application of the procedure is limited to classes from B 7.5 to B 35 according to GOST 17624-87.

Bounce and Impulse Method

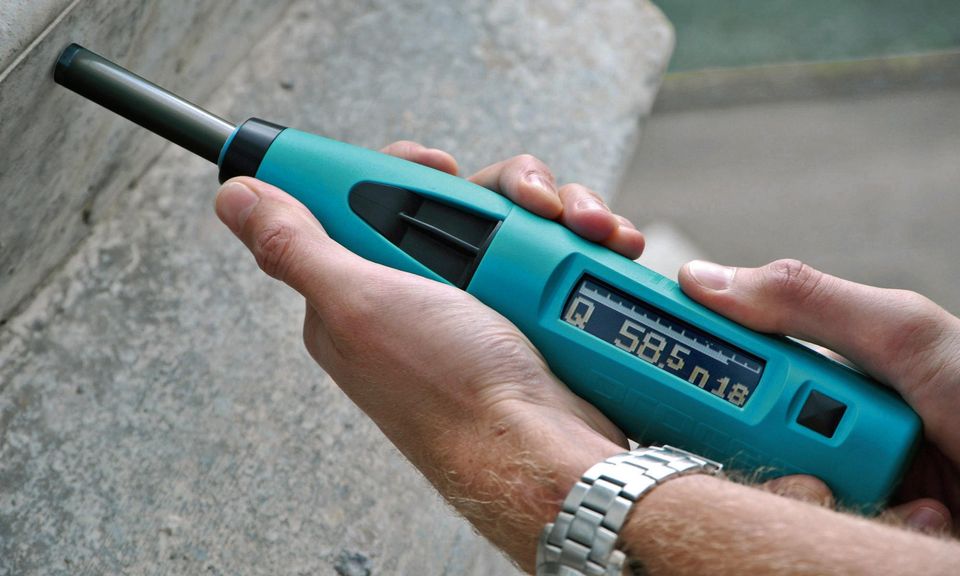

The strength is determined by the method of elastic rebound and shock impulse. Strength is calculated by the speed of ultrasound.

The shock pulse method is to record the impact energy that occurs during the impact of the hammer with a concrete structure. This is a quick and easy way to test your fortress. Using it, determine the class of material. This information can be entered into the computer from the instruments.

A method for calculating reliability by the elastic rebound method is made by a sclerometer. In this case, only the surface hardness of the concrete is measured. Data is written to the log.

A similar method has errors from 30 to 50 percent. Therefore, it is not used when checking concrete products, where accurate results without errors are needed.

Nondestructive testing

Non-destructive testing is carried out by chipping a reinforced concrete rib. In this case, the force applied during shearing is recorded.

Another verification method is peeling off. It is more accurate, but requires a long preparation for holes for installing the anchor and is too time-consuming.

Such tests are important when they want to reconstruct old buildings, carry out repair and restoration work. Because the loads and designs of concrete products are changing. They are used when checking newly constructed precast concrete elements for earthquake resistance.