How to cut a tile - features of cutting a tile with a grinder and a tile cutter

When working with ceramic tiles, it is not possible to avoid cut rows that fit in inconspicuous places. Typically, cut tiles are glued symmetrically to the edges of the walls. The need for cutting tiles arises when lining the walls around doorways, utilities and other obstacles that require careful styling. In any case, the master tiler, especially the beginner, needs to know how to cut ceramic tiles in each case. After all, the technology for performing a direct cut is significantly different from the technology of curly cutting. The right choice of tools allows the master to perform the facing work efficiently and without downtime, and also to prevent a large amount of waste in the form of unevenly cracked tiles.

How to cut tile: video example of work

Tile Cutting Tools

Tile cutting can be carried out not only with special tools called tile cutters, developed by manufacturers specifically for this facing material. Glass cutters, grinders, wire cutters, and electric drills with various nozzles are used, which are also used in cutting other building materials.

Each tool has its own characteristics and tricks of operation, requiring a person who works with him a certain skill, coming with experience. Therefore, experienced craftsmen advise to conduct trial cutting, using one of the spare tiles for these purposes. This will allow you to adapt to the tool and material with small losses.

How to cut tiles with a tile cutter

There are hundreds of models of tile cutters that can be divided into two large groups: manual and electric.

- Manual tile cutters are released in the form of tongs that look like pliers. Using this tool, a neat cut with a diamond cutter is first made on the front side of the enameled tile. After that, using the corner of the tile cutter, the tile is simply broken off. Special skills are not required, so the tool is suitable for beginner amateur masters.

- Tabletop models of manual tile cutters with different base lengths are used for cutting tiles whose thickness does not exceed 15 mm. For example, cutting tiles 8 mm thick, used for wall cladding, is carried out by a tile cutter, the length of which does not exceed 400 mm. Some models equipped with a circular cutter, in addition to straight cuts, are able to make rounded holes with a diameter of up to 80 mm.

Important! When choosing a manual tile cutter, pay attention to the method of moving its tool holder along the guides. It is better to give preference to tools in the design of which self-lubricating o-rings or bearings are used.

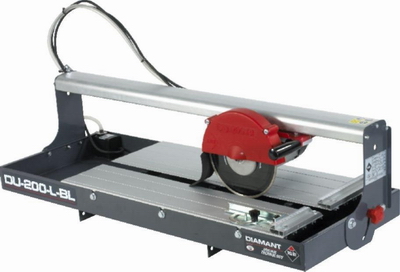

- Electric tile cutters are used when carrying out facing works in large volumes. This power tool is indispensable when cutting thick tiles. Choosing a machine for cutting tiles, look at its power, the value of the diameter of the cutting wheel, the depth and length of the cut, the size of the table, the weight of the tile. It also matters the time during which the machine can operate continuously.

- Electric tile cutters are divided into two types, which differ from each other in the way the engine is placed.Models with a lower motor arrangement are compact in size, therefore they are used when working in small rooms. The upper arrangement of the engine is used in the design of rail tile cutters, which are much more convenient in operation. In addition, the quality of cutting tiles is an order of magnitude higher. The diamond blade in all tile cutters is cooled with water. The advantage of electric tile cutters is their ability to cut ceramic tiles at an angle not exceeding 45 degrees.

Important! When choosing an electric tile cutter, pay attention to both the manufacturer and the technical characteristics of the tool. A good tile cutter is equipped with a rigid base and thick-walled guides.

How to cut a tile grinder

An angle grinder, called by the Russians a grinder in honor of the first manufacturer who began supplying this power tool to Russia. It is a multifunctional tool capable of processing tiles with a diamond cutting wheel. Both straight and figured cutting of the grinder is possible, while the disk is changed to a diamond wheel intended for dry cutting. When performing a cut, it is not necessary to strive to capture the entire thickness of the tile, since it easily breaks along an incised line.

The quality of the edges of the tiles cut by the grinder is lower than when processing with a tile cutter, but it does not require preparatory work. The disadvantage of using a grinder when cutting tiles is the formation of a large amount of dust and fragments scattering in different directions. Therefore, the master tiler must work in goggles, gloves, observing all safety requirements.

How to cut porcelain tile

For cutting porcelain tiles use grinders, small and medium, with a diamond blade. There are several types of diamond discs:

- for dry cutting;

- for wet cutting;

- ventilated;

- unventilated.

Porcelain is best cut with a ventilated diamond disc, because during operation it overheats and requires additional cooling. At the same time, diamond blades provide cutting precision and tile cut adjustment. The disadvantage of using a grinder for cutting porcelain tiles is the increased level of dust and noise. It is convenient to cut porcelain tiles using special machines designed for wet cutting. At the same time, the cut of the tile looks smooth and even, there are no chips.

As you can see, cutting ceramic tiles is carried out in various ways, from which you can always choose the most convenient. To drill holes in the tiles, victorious drills are used, as well as circular saws and ballerinas. We hope after reading this material, you will not have questions about how to cut tiles. You will definitely know which tool to buy or rent in a specialized store.

4 comments