Can a SIP panel floor serve as the basis for a bulk floor?

Can bulk floors be used on SIP panel floors? If so, which ones do you prefer: epoxy or polyurethane? Thank.

Self-leveling floors have long been used in industrial construction primarily as a way to protect concrete floors from exposure to high humidity and aggressive environments. In residential construction, polymer blends are widely used both as the main floor and as a self-leveling base for any finishing floor covering.

Concrete is recognized as an ideal base for self-leveling floors, but the manufacturers of mixtures assure that, following the instructions, they can be mounted on any other base from ceramic tile to wood.

Considering that the strength characteristics of SIP panels are much higher in comparison with the properties of similar wooden structures, they can well serve as the basis for a bulk floor. On the other hand, compared to concrete, sandwich panels are more sensitive to vibrations, which in large rooms can lead to cracking of the polymer flooring.

In Russia, there are no GOSTs and TUs that regulate the norms and criteria for using SIP panels, and therefore you can only be guided by the manufacturer's instructions for the construction of frame houses. They usually assure that SIP floor panels are an ideal base for any finishing coating and even recommend that bulk floors be made in bathrooms and kitchens.

When choosing between epoxy and polyurethane polymer mixes for floors, consider the operating conditions, the purpose of the room, the type of heating system and your budget.

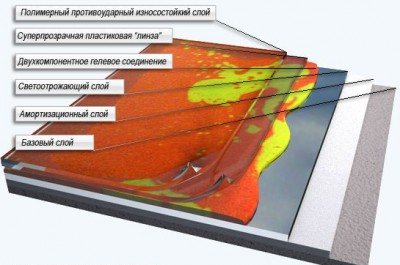

- Epoxy bulk floors are two-component mixtures that completely harden within 48 hours. They are resistant to high humidity and chemical environments, do not smell when applied, are durable and pleasing at affordable prices. Suitable for bathroom and kitchen. The disadvantage is fragility. That is, in rooms of a large area and in the case of a sharp temperature difference, they can crack.

- Polyurethane mixes for bulk floors can consist of both two and one component, which greatly facilitates the preparation and application of the composition to the base. Dry completely within 24 hours. Resistant to high humidity and chemicals, wear-resistant, durable and flexible. Suitable for all types of rooms and serve as an excellent basis for any floor heating system. The disadvantage is the pungent smell of the mixture, which completely disappears during ventilation.

- Methyl acrylate bulk floors are strong, flexible and durable, do not respond to temperature changes and are suitable even for unheated rooms. True, it is possible to work with methyl acrylate polymer mixtures at a temperature of at least 20 ° C.

When buying a polymer mixture, be sure to read the manufacturer's instructions and make sure that it is suitable for a non-concrete base.